SmartHaulage

RFID Ore Tracking For Mines

An Automated Ore Flow Tracking System

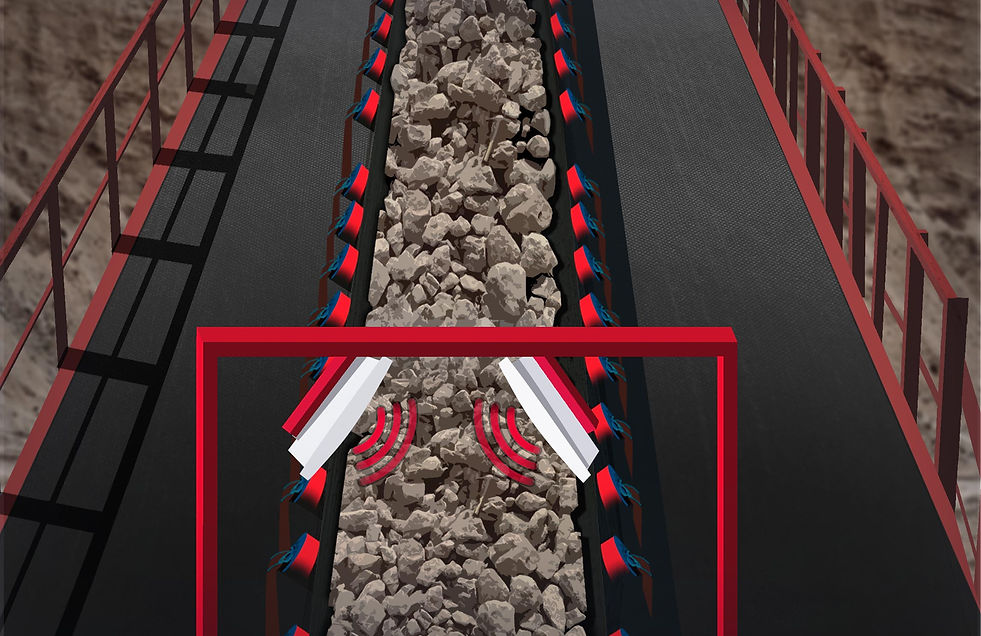

Many mining companies struggle to keep track of the origin and movement of their conveyed ore and waste flows. Washers, wooden blocks and metal balls are often used, but are not always effective. With OreTracker, the ore tracking process is automated through the use of RFID tags and scanners, providing an efficient solution for mines to keep track of the origin and movement of the ore and waste flows.

How OreTracker Works:

-

Robust, blast-resistant RFID tags are deposited at different points in the ore and waste flow.

OreTracker and its Cloud-based System:

All data captured by RFID scanners is stored locally on each device before being synchronized and uploaded to the Cloud in real time.

An authorized employee can access reports such as:

Ore/Waste Origin: A log report with the date, time and location for when ore left its origin.

Ore/Waste Movement: A log report with the date, time and locations at which the ore flow passed scanner points.

OUR RFID SYSTEMS

OreTracker

Keeping track of your ore flow

-

Fixed RFID scanners are installed at key points next to conveyor belts.

-

The tag data detected by scanners is uploaded to the Cloud in real time, where authorized employees can view records of ore and waste origins and movement.